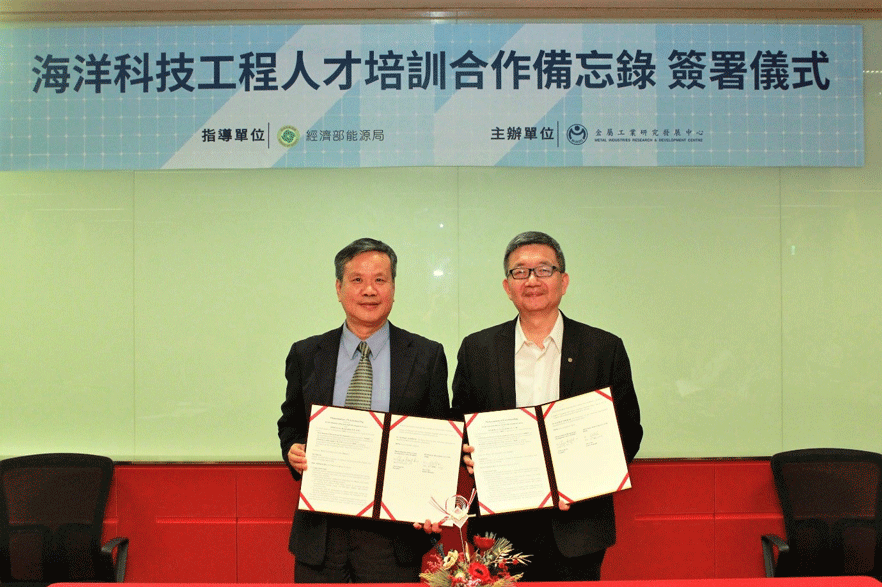

In April 2019, POSH Kerry Renewables ("POSH Kerry") was invited to partner the Metal Industries Research & Development Centre ("MIRDC") to train local maritime talents in areas covering Dynamic Positioning ("DP") training, at Taiwan's first specialised Maritime Training Centre.

The company signed a Memorandum of Understanding ("MoU") with MIRDC - an agency under the umbrella of Taiwan's Ministry of Economic Affairs - to join leading maritime companies Maersk Training and DNV GL to develop professional courses across various specialties. These courses will uplift Taiwan's maritime capabilities by developing local expertise for both onshore and offshore talent.

The maritime training centre is scheduled for completion in 2020 and will be located within the vicinity of Shin Da Harbour in Kaohsiung.

Mr Kelvin Teo, Managing Director, POSH Kerry, said, "We are excited to contribute towards the establishment of Taiwan's first specialised Maritime Training Centre, especially in the area of DP training. In sharing our expertise and providing on-the-job training on board our large fleet of DP offshore vessels, POSH Kerry will do its part in cultivating a pipeline of local talent who can anchor the government's plans to advance its offshore renewable energy and marine industries."

As a Taiwan-based integrated solutions provider, POSH Kerry is able to lend its expertise to develop DP training curriculum that are accredited by The Nautical Institute. The company will provide trainers for these courses, as well as offer attachment opportunities for trainees to serve as DP operators on our vessels. The partnership with MIRDC reaffirms POSH Kerry's commitment to support the offshore renewable energy and maritime development goals for Taiwan.

For more information on POSH Kerry Renewables, click here.

POSH is proud to play its part in supporting the continued growth of the offshore renewables sector.

Last year, we re-purposed our 7,000 BHP AHTS POSH Daring to support construction work on the 109.2MW Chuanghua offshore wind farm near central Taiwan.

Commissioned by Per Aarsleff, POSH Daring helped to create an air bubble “curtain” through hoses on the seabed. This dampens construction noise, thereby reducing the impact on surrounding marine life.

In keeping with our vision to be a sustainable solutions provider, we seek to conduct business in a way that prioritises the well-being of our environment, while meeting our clients’ needs.

#offshoremarine #offshorewind #offshorecrew #AHTS #bubblecurtain #sustainableenergy

Today we’re revisiting our impressive harbour tug tow for Noble Corporation!

#DYK that aside from being a major operator of offshore support vessels, POSH is a Maritime and Port Authority of Singapore (MPA) licensed harbour tug operator and in fact has the widest tug base coverage in Singapore? Not only that, we have had zero service failures in our 24/7 operations!

In March 2019, our POSH harbour tugs towed the Noble Joe Knight jackup rig from our sister company PaxOcean’s Graha shipyard in Batam to the Sembcorp Marine Integrated yard in Singapore. The Noble Joe Knight is the second jackup rig Noble purchased from PaxOcean.

#offshoremarine #tug #jackuprig #MPA #DYK #throwbackThursday

Today we’re revisiting our impressive harbour tug tow for Noble Corporation!

#DYK that aside from being a major operator of offshore support vessels, POSH is a Maritime and Port Authority of Singapore (MPA) licensed harbour tug operator and in fact has the widest tug base coverage in Singapore? Not only that, we have had zero service failures in our 24/7 operations!

In March 2019, our POSH harbour tugs towed the Noble Joe Knight jackup rig from our sister company PaxOcean’s Graha shipyard in Batam to the Sembcorp Marine Integrated yard in Singapore. The Noble Joe Knight is the second jackup rig Noble purchased from PaxOcean.

#offshoremarine #tug #jackuprig #MPA #DYK #throwbackThursday

As a leading offshore marine player, POSH is continually looking to expand its scope of services to meet the dynamic needs of the offshore marine industry. In 2018, we expanded into the subsea space, leveraging off our diversified fleet to provide clients with an integrated suite of subsea services. These include support for subsea Inspection, Maintenance and Repair ("IMR"), and construction and installation works.

Shortly after its establishment, POSH Subsea was awarded its maiden to support the construction and installation works for a pipeline replacement project for a National Oil and Gas company off the west coast of India. The project was supported by PW Natuna - an accommodation barge that was re-purposed into a Dive Support Vessel ("DSV") for the job - and two Anchor Handling Tugs, Maritime Putri and Maritime Putra.

Equipped with advanced saturation ("SAT") and air dive systems as well as a Remote Operated Vehicle ("ROV"), PW Natuna operates as an installation vessel that allows subsea installation works in depths of up to 100 metres. The SAT system allows divers to work for up to 28 days by housing them in chambers pressurised to the depth of the worksite. A separate pressurised chamber is then deployed to transport them to and from the site.

In the first quarter of 2019, we clinched our second contract for POSH Subsea with a leading global integrated oil and gas services company. This contract is for spool installation and pipeline crossing works for a pipeline replacement project off the west coast of India.

As we continue to meet our clients' needs with our quality offerings, we hope that these service contracts are the first of many to come for POSH Subsea.

Dive system providers are developing bespoke solutions for subsea vessel owners

Looking to offer integrated diving solutions on its vessels, Singapore-based POSH Subsea inked a deal in January with Unique Group to design, manufacture and deliver classed air and saturation dive systems.

Over the next two years, Unique Group will supply classed air and saturation diving equipment, compliant to the stringent Oil and Gas Producers (OGP) 468 and International Marine Contractors Association (IMCA) guidelines, as well as consumables and technical support during and post installation.

POSH Subsea, a unit of PACC Offshore Services Holdings Ltd, operates specialised vessels capable of supporting subsea inspection, repair and maintenance (IRM), construction and installation.

To minimise operational downtime, Unique Group is supporting the contract with its Unique Equipment Manager (UEM), a digitalised planned maintenance system that integrates with the dive systems to enable POSH to track the condition of the equipment more accurately.

Subsequent to its contract with POSH Subsea, Unique Group secured an order from Kazakhstan-based subsea services provider FSDS Group for a bespoke air dive systems. In June, Unique Group’s Diving & Life Support division in Sharjah delivered such a system in eight weeks.

ABS classed and built to IMCA guidelines, the diving system comprises a dive control station, diver decompression chamber, diver monitoring and life support, air storage, high- and low-pressure compressors and main diver and standby diver hot water machines.

FSDS Group chief executive Matt Richards, said: “Our technical team worked rigorously with the engineering team at Unique Group to ensure that the system was designed to our specific requirements.”

UK-based JFD, part of James Fisher and Sons plc, was similarly challenged in September with an order to deliver saturation diving products rated to a depth of 500 m. JFD designed and delivered the new products as part of a saturation diving system for a leading offshore service provider.

For the contract JFD developed new environmental control systems, gas reclaim and life support products that provide saturation dive capability. To meet the requirement for 500 m-rated products, JFD updated its existing technology to provide greater performance capacity, as well as developing entirely new products, all of which had to be verified and proven at this lower operational depth. The new technology utilised by JFD has enabled products to be designed that are able to cope with increased pressure, increased ability to heat and which cool the divers’ living environment; they also offer increased transfer of gas and fluids at extreme operational depths.

JFD has previously modified its range of equipment to meet customer requirements. In 2014, as part of a saturation diving system built for the Russian Navy to support submarine rescue operations, JFD’s saturation diving products were enhanced for 450msw operation and incorporated within the diving vessel Igor Belousov.